A system building solution made of prefabricated solid wood components for multi-storey residential construction that can be individually configured.

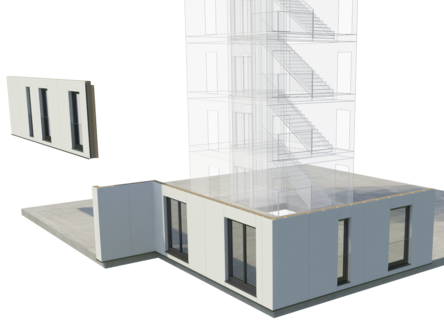

1. Wall modules

The highly industrially prefabricated precast walls, so-called flatpacks, offer sufficient scope for individual planning. The width and height of the walls and also the position of the window and door openings can be individually selected. The construction of the individual wall structures, on the other hand, is unalterably defined as a system. This results in the decisive advantage of the standardised and thus industrially producible flatpacks.

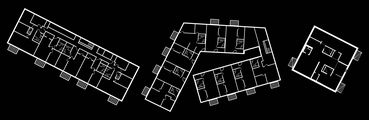

b_solution is suitable for different building site requirements. b_solution’s system corners offer high planning and concept flexibility. Flexible corners ranging from 70 to 110 degrees offer great freedom when designing the ground plan.

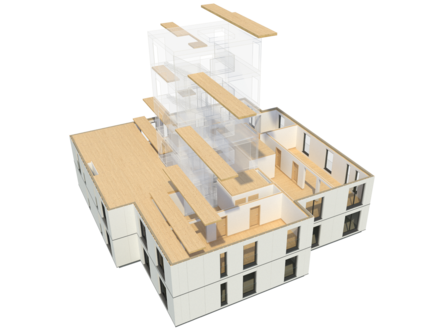

2. Ceilings and roofs

All BBS ceiling and roof elements are delivered directly from the binderholz plants to the construction site - ready to be cut to size and installed quickly, dryly and quietly. The remaining structural components, such as floor heating systems or floor coverings, are then carried out on site. The finely sanded, smooth wooden surfaces of the ceiling and roof elements give every room a warm and comfortable ambience. No matter whether they're left natural or colourfully designed.

3. b_box

The b_box combines 3 functions in 1 room module. Standardised building services, well-equipped premium bathroom and static load-bearing effect. Furthermore, we manufacture each b_box in our serial production plant - with quality assurance.

Combination hybrid distributor

All flat distributors and connections are easily accessible in the so-called combined hybrid distributor directly next to the b_box entrance door. Electrical, cold and hot water, heating, pumps, ducts, fire bulkheads, ventilation, moisture sensors and many other mechanical, electrical and plumbing equipment (MEP) are system-based, certified and pre-installed in the b_box. A b_box can be produced in 4 to 8 hours and installed on site in just 20 minutes. The entire MEP planning of the b_solution building structure comes from us. MEP - tidy, compact and carefree.

Equipment levels

Shower or bathtub, single or double washbasin, barrier-free and with washing machine connection - the b_box is also a fully tiled and equipped bathroom with toilet. Optionally, the equipment levels 'pure' or 'high' are available. The bathroom ceiling is a modern design in white glazed wood, making every occupant feel at home.

Made entirely of solid wood elements (CLT BBS), the b_box systematically fits into the entire b_solution construction as a load-bearing and stable modular unit.

JUST PLAN IT!

It has never been so easy to design a multi-storey residential building. With b_solution, you get a plug-in for your CAD system that allows you to assemble the system components for your project individually. From regional and national building laws to regulations for fire protection and statics-everything has already been considered for your project.

The digital twin

Once the customer has completed the planning and configuration of the desired building project and sent it to us, the b_solution system software automatically generates a three-dimensional digital twin of the designed building in a very short time, meaning that the building is ready for production and construction down to the last detail, and is also available with a complete cost calculation. This is made possible by digital cataloguing of all construction and equipment variants coupled with the definition of b_solution industry standards.

Configuration and equipment options can be altered at any time on the digital twin, and the cost calculation will be adapted accordingly. Once the final configuration has been determined, the digital twin is 'frozen', i.e. finalised. From this point on, several standardised processes run simultaneously in order to industrially and automatically produce the b_solution kit and to ensure that the building is assembled and completed on schedule and with quality assurance.