15.03.2021

Post-compression with b_solution | it is so easy

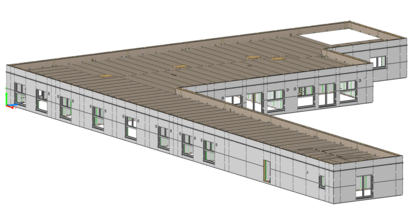

The b_solution project HK Holding in Wals, Salzburg, impresses with its simplicity. A factory hall will be expanded by 1,000 m² of office space and an apartment without covering off even one square metre of undeveloped green space.

With the b_solution system, it was possible for the architects to plan the building easily and quickly with the help of the b_solution CAD plug-in and the customisable system components and to immediately obtain it as a 3D model with all system details and equipment information. The digital twin generated in this way is the basis for the fast, sound and accurate cost calculation for the construction project. Regional and national building laws as well as regulations for fire protection and statics were already pre-set for the construction project.

The building is accessed via a stairwell core with a lift shaft. Despite the high degree of industrial prefabrication of the wall modules, it is possible to plan the width and height of the walls as well as the position of the window and door openings as desired. Only the wall structure is clearly defined - because this has the decisive advantage of enabling the use of standardised, industrially produced flatpacks, as the wall modules are called.

All wall and roof components are made of fully load-bearing binderholz CLT BBS. At the bottom of the roof elements, the wood surface of the solid wood elements is executed in visible quality and thus appears as natural wood in the interiors.

The so-called b_box is used in this project for the provision of the sanitary facilities on the premises. The prefabricated room module, which is finished down to the last detail, includes the complete technical installations as well as the wet rooms (bathroom/toilet). The installation of sanitary units, including the complete building technology, has never been faster and easier, as all supply and disposal lines as well as the connections for electrical, heating, water and media are already installed or fitted at the factory. On site, these only had to be connected via plug connections and sliding sleeves.

Continuous quality assurance and certification as well as 100% planning reliability due to complete digitisation of the quotation, planning, production and construction processes up to handover as well as the traceability and transparency of all processes round off the b_solution concept.